STAINLESS STEELWhat is Stainless Steel?

Stainless steels are iron alloys with a minimum of 11% chromium. Other alloying elements are added to enhance their structure and properties such as formability, strength and cryogenic toughness. These include metals such as Nickel, Molybdenum, Titanium & Copper. Stainless steels are sometimes called corrosion-resisting steels since the term stainless may suggest non-staining. It does not mean non-staining in all environments, but less staining and more resistant to corrosive attack when compared with steels containing under about 11% chromium. What makes stainless steel resist corrosion? Chromium (the key element in stainless steels) in excess of about 11% forms a tenacious, refractory oxide, protective film on any exposed layer, ie, a corrosion barrier. This relatively impervious film is considered to be self-healing or self-restoring. It will, if broken, repair itself spontaneously upon re-exposure to an oxidizing agent such as air or nitro acid. Resistance to corrosive attack under specific conditions is enhanced by progressively increasing chromium over 11% and/or by the addition of other elements such as nickel, molybdenum and copper. What Makes Stainless Steel a Sustainable Material? Before we can determine whether stainless steel is a sustainable material, we shold first define what we mean by sustainability in relation to what is known as the triple bottomline: People, Planet and Profit. 1. PEOPLE The material, in its use or in its production process, respects the human being, especially in terms of health and safety. A sustainable material does not harm the people working to produce it, or the people who handle it during its use, recycling and ultimate disposal. Stainless steel is not harmful to people during either its production or use. A protective layer protects forms naturally on all stainless steels because of the inclusion of chromium. The passive layer protects the steel from corrosion -ensuring a long life. As long as the correct grade of stainless is selected for an application, the steel remains inert and harmless to the people who handle it and the environment. These characteristics have made stainless steel the primary material in medical, food processing, household and catering applications. 2. PLANET The emission footprints of the material, especially those related to carbon, water and air, are minimised. Reuse and recyclability are at high levels. The material has low maintenance costs and a long life, both key indicators that the impact of the material on the planet is at the lowest levels possible. Stainless steels are easily recycled to produce more stainless steels and this process can be carried on indefinitely. It is estimated that about 80% of stainless steels are recycled at the end of their life. As stainless steel has a high intrinsic value, it is collected and recycled without any economic incentives from the public purse. 3. PROFIT The industries producing the material show long-term sustainability and growth, provide excellent reliability and quality for their customers, and ensure a solid and reliable supply-chain to the end consumer. Choosing stainless steel for an application ensures that it will have low maintenance costs, a long life and be easy to recycle at the end of that life. This makes stainless an economical choice in consumer durables (such as refrigerators and washing machines) and in capital goods applications (such as transportation, chemical and process applications). Typical steel production technology

|

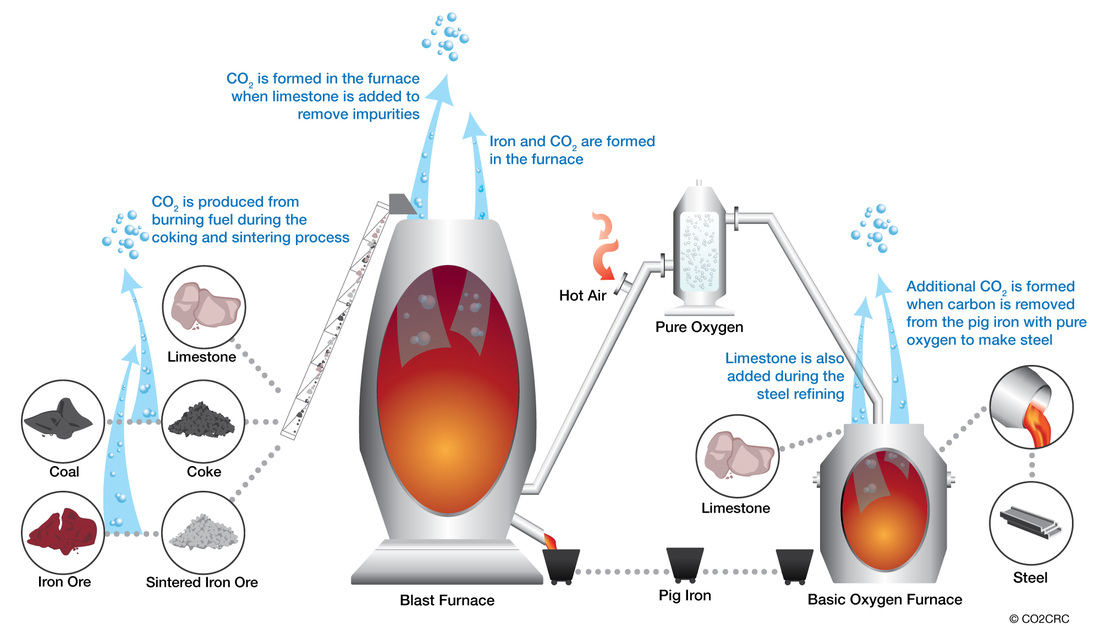

The process of making iron and steel creates CO2 emissions through the use of fuel for energy and the use of coke and limestone.

CONSERVES ENERGY

Some building materials need to be treated before it is able to conserve energy. For instance, if you do not use stainless steel material to transfer and preserve the coolness of an air conditioning then the results can be unpredictable. Save yourself the headache. Stainless steel comes with a highly solar reflective index value that does not need to be applied and reapplied. It is a characteristic embedded into the metal meaning you do not have to waste time, money and material on reapplying and replacing it to ensure energy conservation.

ARCHITECTURE, BUILDING & CONSTRUCTION

Architecture, building and construction is a growing market as many modern buildings use stainless steels for cladding, roofing and facades. Another thing is that the low maintenance cost and anti-vandal characteristics of stainless provides a growing market in public transport, ticket machines and street furniture. Stainless steels are used for construction purposes, as well. When reinforced concrete first started to be used it was considered that the carbon steel used would not rust, as cement, obviously derived from limestone, is alkaline. However, constantly using grit salt on bridges can change the pH to acidic thereby rusting the steel which expands and cracks the concrete. Stainless steel reinforcing bar, although initially expensive, is proving to have very good life cycle costing characteristics.

|

STAINLESS STEEL PROJECTS

Our Clients:

Contact UsTo enquire about our custom stainless steel, copper, brass, zinc designs or fabrication services and custom catering equipment, call one of our friendly staff on 02 4226 5500 or send us an email. ©2016-2024 All Metal and Stainless Solutions Pty Ltd.,

ABN 61 268 309 591. All Rights Reserved. digital: webfx2digital |

Subscribe for updates |